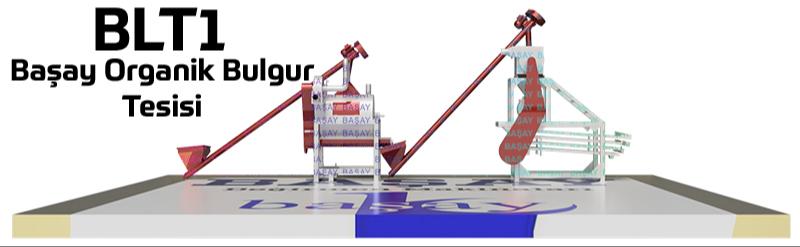

BLT1 Başay Organic Bulgur Plant

Wheat, Siyez, Kavılca Bulgur

In order to naturally transform sun-dried wheat into bulgur with classical stone mills

Main Machines Used in the Facility:

BTC1 Drum Peeler

It is used in the process of separating the grain shell, which is slightly moistened, with a fan. It is important in the production of bulgur.

BBS5KES Bulgur Crusher and Sieve with 500mm Stone

Crushing is done with 50 cm Mills Stone. It is the ideal crushing form for the production of bulgur.

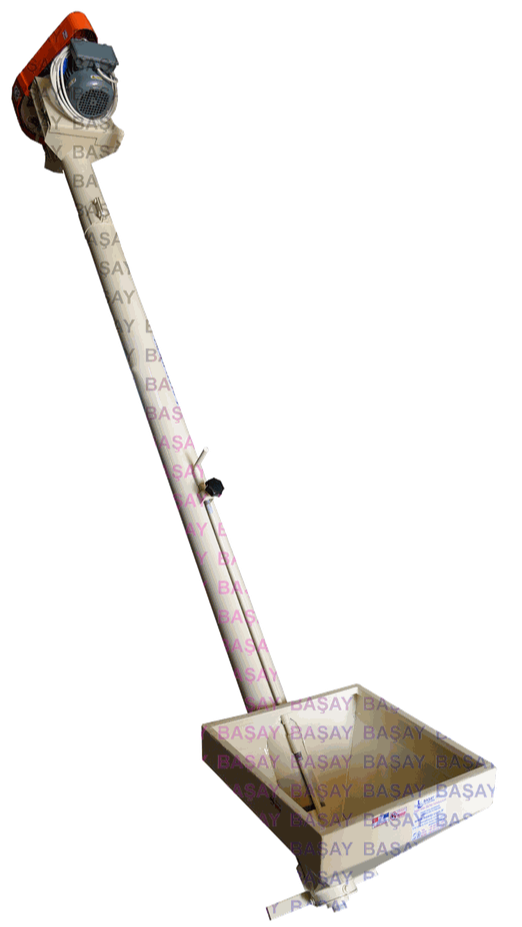

BBH100 Helix Transporter - Worm Drive

It allows products to be transported horizontally at an angle.

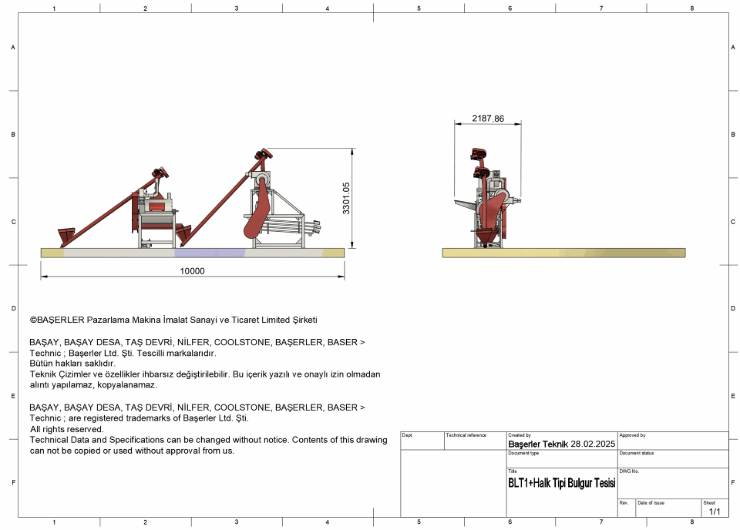

Capacity

400-600 kg wheat processing per hour

Settlement

Height 5 meters, Width 3 meters

Length 12 meters

Energy Consumption

3 Phase 380V 35 kw / hour

BAŞAY BULGUR PLANT Use of Machines

BAŞAY BBT 100 Pre-boiled and dried wheat is put into the helix by slightly wetting it.

In BASAY BTC1 Drum Peeler, 80kg of lightly soaked wheat is peeled for approximately 7 minutes. During peeling, the shell is thrown out with the help of the fan at the top.

BAŞAY BBT 100 The hulled wheat is poured by pulling the lever in the machine number 2 and pouring it with a 7-minute process.

In the BAŞAY BBS5KES Bulgur Crusher and Sieve machine, the peeled wheat is first thrown again, crushed with a special stone and divided into classes.

You can adjust the size of the bulgur according to your needs with the adjustment wheel on the millstone part.

BULGUR making and techniques A

Bulgur is a food product specific to Turks and its consumption has an important place in our country.

However, its quality is not always possible at the desired level. Although there are various reasons for this, the most important ones are the failure to select suitable raw materials and production with primitive technology.

bulgur is produced at homes, workshops and factories in Turkey. Although bulgur is produced with almost the same method in houses and workshops, production is made with a slightly different method in factories.

In this document, we will focus on the bulgur processing technique and issues to be considered in homes and workshops.

BULGUR PRODUCTION STAGES

In our country, durum wheat is preferred in the production of bulgur. This wheat is a hard type of wheat and provides the bulgur with a shiny structure.

The main types of durum suitable for making bulgur are Şahman, Karakılçık, Kundura, Çakmak 79 etc. dir. In addition, attention should be paid to the low amount of rotatable grain in these wheat.

If durum wheat is not found, it can be used in making bulgur in common wheat. However, it is important that the wheat is hard bread wheat and is white in color.

If the wheat is soft, mush will occur during production and when it is cooked at home. On the other hand, its side view is matte and the taste is negatively affected.

We can examine the production of bulgur from wheat in 8 stages. These are wheat, respectively;

1. Cleaning and washing

2. Wetting

3. Boiling

4. Drying

5. Sifting

6.Peeling

7. Crushing and second Sifting

8.Packaging and storage

1. Cleaning and Washing:

After selecting the wheat according to the technique, the wheat should be cleaned from the stalk, straw, stone, soil, foreign seeds and cereal grains that spoil the quality characteristics of the bulgur in cleaning machines or manually.

By using the cleaned wheat several times in the washing containers, dust and soil are completely separated.

2. Wetting:

The cleaned and washed wheat are taken to the soaking boilers and subjected to the soaking process.

The benefit of boiling is to ensure quick gelatinization during cooking by taking the necessary water into the starch in the grain.

Matters to be considered in wetting; Soaking water is clean and germ-free and not too hard water.

3. Boiling:

It is the event that wheat, which has taken enough water in the cooking process, is boiled for 1-2 hours at 95 C. Boiling is the most important process step affecting the quality of bulgur.

Therefore, attention should be paid to the following operations.

- During the boiling of the wheat, the starch is completely gelatinized, but the wheat grain should not be dispersed and the starch should not be released. For this, wheat should be cooked on a very strong fire.

- It should be fully cooked. When the grain is cut in the middle, there should be no whiteness.

- There should be no clumping, sticking, dispersion, darkening in color (burning) in the cooked wheat.

- The amount of water added for cooking should be adjusted well. So; The cooking of the wheat and the gelatinization of the starch should be complete, there should be no white spots in the wheat and the water in the cauldron should be completely absorbed by the wheat.

If there is water left in the boiler, there will be a significant loss in the nutritional value of the bulgur.

After making sure that the wheat is fully cooked, the bottom of the cauldron is extinguished. The cover is removed and the bulgur is mixed with a wooden shovel and then covered with a cloth and left for a while. Thus, the bulgur that is not fully cooked is provided to be steamed.

Wheat can also be cooked under pressure in vacuum boilers. In this picture, the time is reduced to 10-15 minutes.

4. Drying:

Drying is a process applied to reduce the water rate (moisture) of the cooked wheat grain to around 10%.

The boiled wheat is transported to the exhibition areas and spread 1-1.5 cm thick. They are thoroughly dried, mixed occasionally.

The exhibition areas can be made of concrete or of cloth laid on any floor.

Drying under the sun takes a long time. However, drying rooms can be dried in healthier conditions and time can be saved.

Bulgur can be dried in 4-5 hours by giving dry air of 60-70 ° C to the drying rooms with fans. However, the point to be considered here is that if the temperature exceeds 70 ° C, the color of the bulgur gets darker.

5. Sifting

Although it is generally applied, sieving process is carried out in fabricated bulgur production.

With the sieving, the grading of the wheat through sieves, the peeling process is easier and a second cleaning process is done.

6. Peeling:

Baked wheat is peeled and separated from bulgur using various methods.

Slightly tempering the bulgur with water before peeling it ensures that the shell is peeled faster and better.

If the crust of the bulgur is pounded and peeled in stone mortars with wooden mallets in houses, it is peeled off by passing it with steep stones or crushing machines in factories.

The peeled bulgur is kept in exhibitions for a short time and the water given in annealing is evaporated.

7. Crushing & Second Sifting:

The dried bulgur is crushed to the desired size in hand mills or machines specially designed for this job, and then graded through sieves.

Although the size of the bulgur varies according to the usage purpose and habits, generally;

1. Rice Bowl: Coarse bulgur that passes under the sieve with a 2.5 mm pore opening.

2. Meatballs or soups: They are divided into two as fine bulgur that passes under the sieve with a mesh opening of 1.5 mm.

Smaller bulgur are called sieve and they are either thrown away or used for other purposes.

In the crushing and sieving process, some fine bran is released and this is removed from the environment by air circulation.

8. Packaging and Storage:

Bulgur is new and does not spoil the substance in it. It should be stored in suitable packages.

Care should be taken to ensure that the place where bulgur is stored is cool and not damp. If the environment is damp or if the bulgur is not dried well, mold and other deterioration occur in the bulgur.

If the temperature of the environment is above 30-35 ° C, the bulgur will get sour and open in 4-5 months.

If the place where bulgur is kept is not exposed to direct sunlight and is around 20 ° C, it can last for a year without deterioration in the food value of bulgur.

BULGUR making and techniques B

Bulgur is a semi-prepared food product, preferably obtained by cooking, drying and peeling Triticum durum wheat.

The type of wheat used in bulgur production is one of the main factors affecting the quality of bulgur. Generally, hard wheat, called Triticum durum, is used. This is because hard wheats are bright yellow in color and are richer in protein than other wheats.

If durum wheat is not available, common wheat can be used for bulgur production. However, it is important that the wheat is hard bread wheat and white colored. If the wheat is soft, mush will occur during production and when cooked at home. On the other hand, the appearance is matte and the taste is negatively affected.

When soft water is used in cooking, bulgur has a more attractive, bright-yellow color.

In additive types; tomato paste, broth and enrichment substances (mineral, vitamin, amino acid, etc.) can be used.

We can examine the production of bulgur from wheat in 8 stages, respectively.

1. Cleaning and Washing

2. Wetting

3. Boiling

4. Drying

5. Sifting

6. Peeling

7. Crushing and Second Sifting

8.Packaging and Storage

1. Cleaning and Washing

After selecting the wheat according to the technique, the wheat is made by manually cleaning from the stalk, straw, stone, soil, foreign seeds and cereal grains that spoil the quality characteristics of bulgur or by passing through a sifter with an aspirator. The wheat, which is cleaned, is washed several times and dust and soil are completely separated. In factories producing bulgur, washing is done in centrifuges. Cleaned wheat is stored duly.

2. Wetting

The cleaned and washed wheat is taken into soaking boilers and subjected to soaking. The purpose of soaking is to provide quick gelatinization during cooking by taking the necessary water into the starch contained in the grain. For this purpose, wheat needs to absorb an average of 40% of water. Although the soaking process is usually completed at 60–70 ° C and in 4-5 hours, the best result is obtained at 70 ° C and 5 hours. Usually soaking should be done with water twice the weight of wheat. Care should be taken that the water used is soft, clean and germ-free.

3. Boiling

The cooking of wheat is done to gelatinise the starch in 1-2 hours at approximately 95 ° C of wheat grains that have taken enough water. Cooking is the most important stage for further processing and the quality of the bulgur to be obtained.

Therefore, the following points should be considered;

1. During the cooking of the wheat, the starch should be completely gelatinized, but it should not be exposed, ie the wheat should not be dispersed. For this, wheat must be cooked on a very strong fire.

2. The amount of water added for cooking should be well adjusted.

3. Soaking and cooking are considered together in conventional businesses. The main purpose of soaking and cooking is to absorb sufficient water in the wheat grain at the appropriate temperature and time interval by adjusting the temperature and time together. The water in the boiler must be completely absorbed by the wheat. If there is water left in the boiler, a significant loss occurs in the nutritional value of the bulgur.

4. It should be fully cooked. The cooked wheat should not have white spots, clumping, sticking, darkening in color and gelatinization should be complete.

5. After making sure that the wheat is fully cooked, the bottom of the cauldron is extinguished. The cover is removed and the bulgur is mixed with a wooden shovel and then covered with a cloth and left for a while. Thus, the bulgur that is not fully cooked is provided to be steamed. In modern cooking systems, after the wheat is soaked in water, 4–5 Atm. It is cooked in an autoclave for a few minutes under pressure. With this method, bulgur is produced in a shorter time and with more ideal properties.

4. Drying

Drying is a process applied to reduce the water rate (moisture) of the cooked wheat grain to around 10%. This process can be carried out by laying the bulgur in the sun or in modern tunnel or tower type dryers. The cooked wheat is transported to the exhibition areas and spread in a thickness of 1–1.5 cm. They are mixed occasionally and dried in the sun. In food businesses, wheat is dried up to 10% humidity in drying tunnels with hot fans and in thin wire trays. This process is completed in 4 hours at 60-65 ° C. Keeping the temperature high darkens the color of the bulgur.

5. Sifting

Although it is not generally applied, screening process is carried out in fabricated bulgur production. The dried wheat is separated into sizes by passing through various screening machines. In this way, the peeling process becomes easier and a second cleaning process is performed.

6. Peeling

Baked wheat is peeled with various methods and separated from bulgur. Before peeling, dry bulgur is given 2% water to peel the shell faster and better. While the shell of bulgur is pounded and peeled in stone mortars with wooden mallets in houses, it is peeled by peeling-brushing machines in factories. The shell is separated from the grain by spinning or passing through aspirators. The shell can also split during grinding. During this process, an average of 7% weight reduction occurs. The peeled bulgur is kept in exhibitions for a short time and the water given in the annealing is evaporated.

7. Crushing and Second Sifting

In the classical method, cracked wheat is made in stone mills or manually operated home mills. Roller and hammer type mills are widely used for crushing the bulgur in large enterprises. Crushed wheat is passed through sieves and sorted. Height requests vary according to the purpose of use and regions.

In the bulgur standard no TS 2284, the bulgur is divided into two types as pilaf and meatballs according to their size. Bulgur for pilaf is divided into three types as large, medium and fine according to the grain size, while bulgur with meatballs are divided into two types as large meatballs and thin meatballs. Smaller bulgur is called under-sieve. These are either thrown away or used for other purposes. The fine bran, which is revealed in the crushing and screening process, is removed from the environment by the spinning process or the air circulation system.

8.Packaging and Storage

Bulgur is new, not harmful to health and does not spoil the substance inside, such as sacks, cloth bags, etc. It is placed in suitable packages and stored. Care should be taken to ensure that the place where bulgur is stored is cool and not damp. If the environment is damp, or if the bulgur is not dried well, mold and other deterioration may occur in the bulgur. The temperature of the environment is very important. If bulgur is stored in cotton sacks at 32 ° C, it turns sour in 4 months.

However, if the place where the bulgur is kept is not exposed to direct sunlight and it is around 20-22 ° C at room temperature, it can last for about a year without deteriorating the food value of the bulgur.

Bulgur should be stacked on dry ground and grids in a way that it can be freely walked around, at the same time be well ventilated and not exposed to direct sunlight. It should not be kept together with moist, bad-smelling substances that will adversely affect its taste and other properties, and should be stored at an average of 20 ° C.

According to TS 2284, a good bulgur should have its own color, taste and odor, should not be bitter, rancid, rotten, moldy, should not contain any foreign taste and odor, and the bulgur grains should have a solid, uniform appearance and structure. It should not contain foreign matter. Its moisture should not exceed 13%.

Bulgur average 69.8--73.8 g carbohydrate, 11--13 g protein, 1.5 g fat, 40 mg calcium, 3.5 g iron, 0.40 mg Vitamin B1, 0.06 mg Vitamin B2, 4, Contains 3 mg of niacin.

Bulgur is more nutritious than rice and couscous.

100 grams of raw bulgur contains approximately:

Energy: 281 kcal - Protein: 11 g -Carbohydrate: 73,8 g - Fat: 1,5 g

Total dietary fiber: 23.6 g

* Bulgur is a traditional Anatolian food made from wheat. Foods such as raw meatballs, bulgur pilaf and sterile are made from bulgur, which is offered for sale in two varieties as meatballs and pilaf.

* Bulgur is a very rich food in terms of fiber / fiber, which is known to reduce fat in the blood. It has low carbohydrate value and high protein value. In addition, B1 vitamins in bulgur play an important role in the nervous and digestive system.

* Due to the folic acid it contains, it is a very important food for children and pregnant women.

* It has unsaturated fat and is a healthy nutrient since its total fat ratio is low.

* It does not contain cholesterol.

* Phytic acid, which is the biggest disadvantage of cereal products, is not found in bulgur due to the cooking and drying processes of bulgur.

* Due to its high mineral and cellulose content, it accelerates nutrient absorption, prevents constipation and bowel cancer.

* When mixed with legumes, it becomes the most important food source in the world.

* It does not absorb radiation and is resistant to radiation. For this reason, it is one of the products kept in stock for military and civilian purposes in some countries against nuclear wars.

* Since the nutrients in the germ part of the grain penetrate into the grain during the cooking process, its nutritional value is higher than other products (bread, pasta).

* Due to the cooking and drying processes, it is resistant to mold growth and its shelf life is longer than other products.