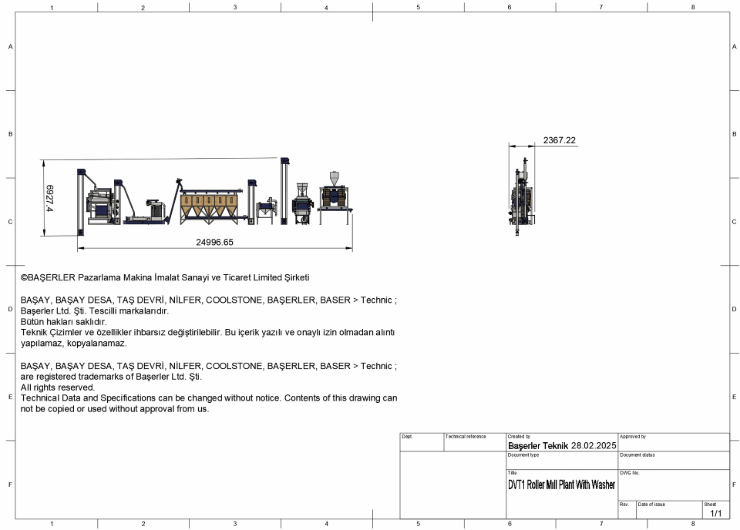

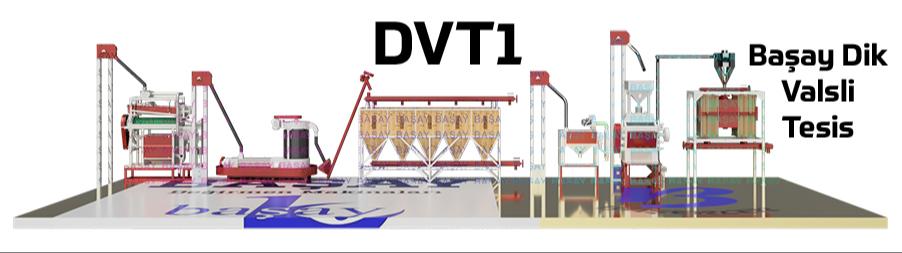

DVT1 Başay Vertical Roller (with Full Washing) Mill Plant

Başay Vertical Roller Mill Plants are the basis of the modern steel roller grinding system. Wheat is turned into flour in one step.

Main Machines Used in the Facility:

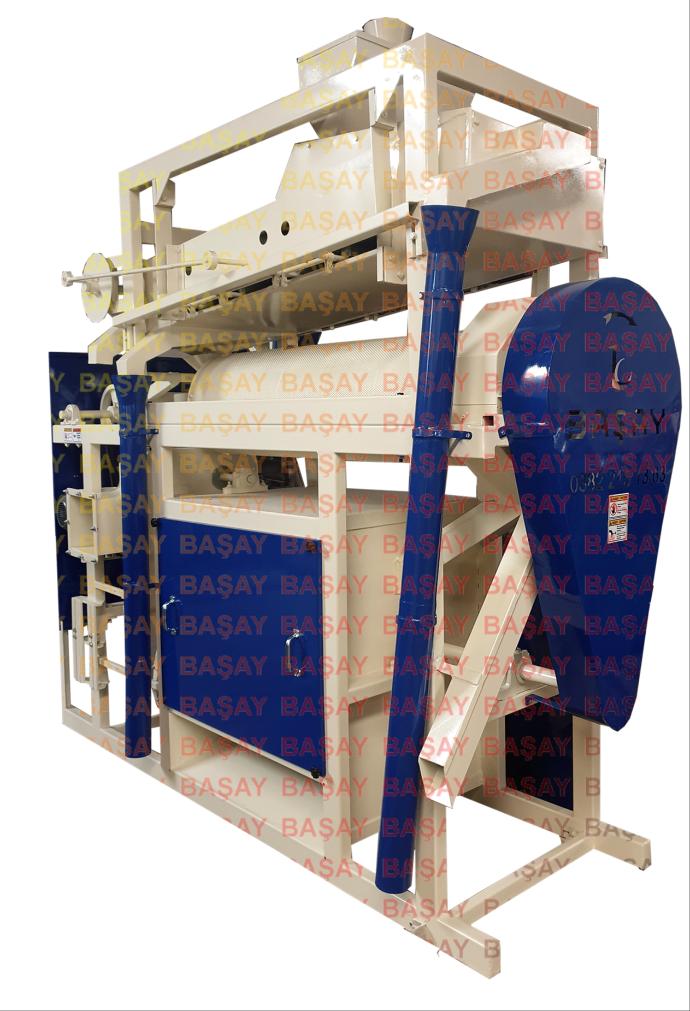

BBT1TF Wheat Cleaning Selector with Brush and Trieur

It is a Başay R&D product that cleans the wheat by air, sieve and shaving and separates it from foreign seeds with a trieur.

BDY1 Vertical Wheat Washer and Dryer

The process of washing the wheat with water is to remove it from the foreign materials. Helps to remove garbage, straw and stone from wheat.

BTA5000 Wheat Dampening Store 5 Tons

After wheat is washed, it stays in this wood stores to naturally evaporate water.

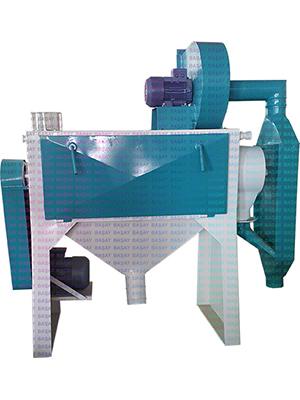

BKS1 Intensive Scourer / Shell Peeler

For gentle peeling of the outer skin of the wheat. It is recommended to be used after washing and tempering.

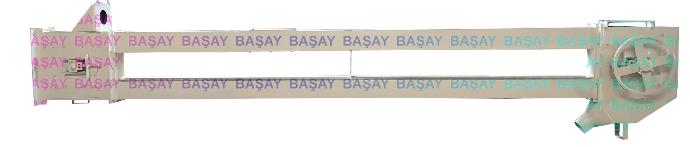

BDV1 Vertical Roller Mill

Wheat or similar grains processed into flour in one step.Can work as a stand-alone mill, which fits most of the flour mill buildings.

BSE214 Two Passage 14 Layers Plansifter

This plan sifter has been designed for the sifting of granular and floury products as well as for the sorting of different products in wheat, rye, corn (maize) and buckwheat mills.

BEF405 Fan

It allows the products to be transported by the air generated by the fan.

BET100 Bucket Elevator

It enables the products to be raised vertically to the desired height.

BTS76 Cyclone

It provides the separation of flour and air.

Capacity

400-600 kg wheat processing per hour

Building

Height 5 meters, Width 3 meters

Length 20 meters

Energy Consumption

3 Phase 380V 70 kw / hour

Water Usage

1000-2000 liter /hour

Efficiency

Flour 1 %60-65

Flour 2 %10-15

Bran %20-25